I-Tech AB, developers of the antifouling technology, Selektope®, has signed a joint development agreement with IFF Microbial Control, providers of SEA-NINE™ 211N, and developers of the new SEA-NINE™ ULTRA marine antifouling agent technology.

The two entities seek to explore technical opportunities by combining their respective technologies, which together can offer high performance, sustainable and regulatory compliant solutions against the wide spectrum of marine fouling species. Selektope offers a novel approach to repel hard fouling organisms efficiently from a submerged surface, while IFF’s SEA-NINE™ platform offers efficient protection against soft fouling and long-lasting performance during the service life thanks to their new encapsulation technology. Both technologies belong to a rare set of active agents that are approved by regulatory bodies in leading nations for ship repair and new ship building.

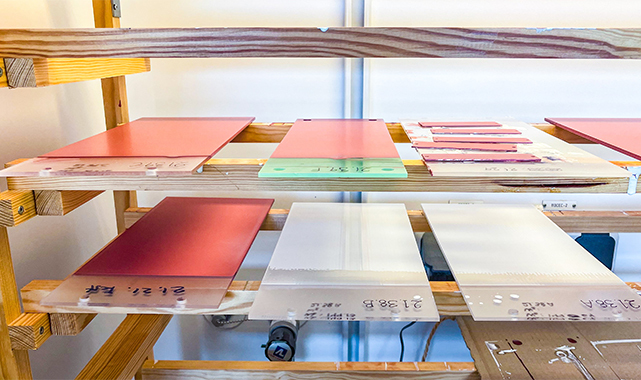

Through the collaboration, both parties will work together to develop active ingredient compositions that would comprise a range of combinations of Selektope, SEA-NINE™ 211N and SEA-NINE™ULTRA, together with other commonly used ingredients for marine antifoulant applications. Joint investments will include R&D activities where such will be tested in marine environments and analysed to identify potential benefits of using a combination of the technologies in antifouling systems.

Dr Markus Hoffmann, Technical Director of I-Tech AB said: "The market demand for premium sustainable antifouling paints, that are both well-suited to specific ship trading patterns and varying activity levels, in addition to protecting against both soft and hard fouling, is increasing. This collaboration is exploring innovative solutions to meet the future demands of fouling protection. Our combined products are complementary, and the knowledge created in this project will enable our customers to offer new solutions for fouling prevention.”

David Laganella, R&D Director of IFF Microbial Control said: "We believe that the benefits of our combined technologies, technical expertise and R&D capabilities can go beyond performance improvements and incremental changes in formulation compositions. The results to come could open new ways for the industry to approach copper free formulations, for safer, more cost effective and more sustainable solutions for both humans and the environment.”