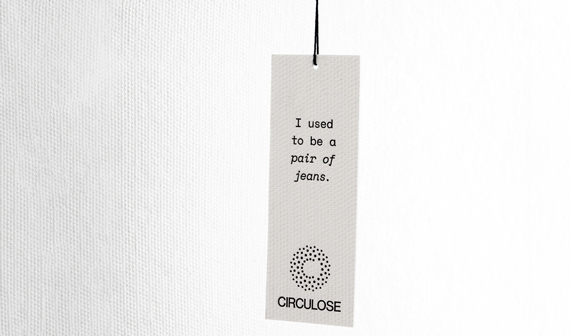

Nouryon has signed an agreement with Renewcell to provide speciality chemicals and engineering solutions for its new textile recycling plant in Sundsvall, Sweden. The facility will recycle textile waste, including items such as worn-out jeans and production scraps, to manufacture 60,000t of Circulose® dissolving pulp per year.

The facility is the first of its kind in the world and could potentially save hundreds of millions of garments from landfill and incineration each year, contributing to a reduction in greenhouse gas emission from the textile industry. Operations on the facility are scheduled to begin in the first half of 2022.

"Nouryon is thrilled to support novel solutions such as this one, which accelerate the growth of the renewable fibres industry, leverage our essential chemistry and speciality solutions and underpin our commitment to a sustainable future,” said Antonio Carlos Francisco, Vice President Renewable Fibers at Nouryon.

New sustainable textile fibers, such as Circulose®, are a substitute for cotton and non-biodegradable fibres, such as polyester. The use of recycled materials in textile manufacturing is expected to play a critical role in reducing the impact of the textile industry on water, land and other natural resources.

Patrik Lundström, CEO of Renewcell, said: "Our mission is to change the global fashion industry. Nouryon is a reliable and well-respected solutions provider to the regenerated fibre industry so we are pleased to partner with them as we embark on this ambitious journey. Nouryon’s experience with innovative, sustainable solutions will play a significant role in the long-term success of our mission.”

"The positive environmental impact of the textile industry’s new sustainable fibres and its potential growth are goals that Nouryon strongly supports,” said Johan Landfors, President Technology Solutions at Nouryon."We are pleased to partner with Renewcell to grow this sustainable industry based on our core competence in renewable fibres chemistry and our engineering capabilities,” Landfors added.